Batteries for Mobile Robots

1. Chemical Energy

Mobile robots move – therefore we need to

consider the important question of where the energy required for locomotion

is going to come from. In the case of large robots we would like to be able

to drain energy at high peak rates. For smaller robots, we would like to have

enough energy for several hours of continuous work. Internal combustion engines

are out of the question, since the robots we are considering will be used

indoors. Fuel cells, which combine hydrogen and oxygen, and do not produce

toxic gases, will be an interesting source of energy in the future, but the

technology has not yet matured for the kind of applications we consider here.

Therefore we need to use some form of electrical energy stored in rechargeable

batteries.

The electrical battery was invented several

centuries ago. Rechargeable batteries have been around for many decades and

are improved continually, from year to year. A battery consists of a negative

and a positive electrode. Each electrode is made of a different material and

there is a chemical reaction in the interior of the battery, a different one

for each electrode but complementary. A modern battery can be understood,

as a first approximation, as a kind of sandwich in which the top and bottom

materials are the electrodes, and the material in the middle is the electrolyte.

The electrolyte makes possible the chemical reactions inside the battery and

transports ions from one electrode to the other. The electrolyte is also a

reservoir of ions for the chemical reactions needed at the electrodes.

Summarizing: a battery transforms the chemical

energy stored in the battery’s material in electricity. Batteries which cannot

be recharged are called primary batteries; rechargeable ones are called secondary

batteries. We are interested here in rechargeable batteries, since primary

batteries are too expensive in the long run.

2. Electrolytes

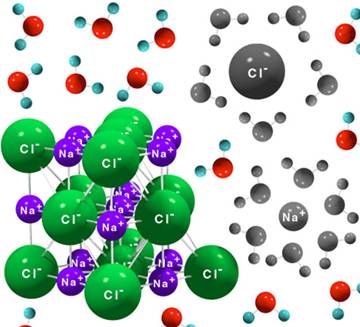

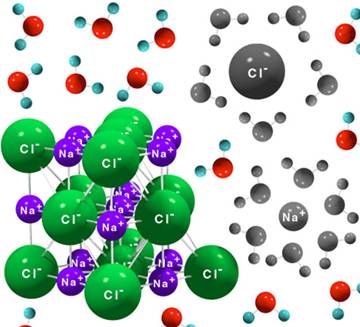

There are many spontaneous chemical phenomena

triggered by the contact of one substance with another. Many salts, for example,

readily dissolve in water and form ions. Table salt consists of sodium (Na)

and chloride (Cl). When put into water, the sodium atoms separate from the

chloride atoms. Water molecules are tightly bound whereas NaCl has weak ionic

bonds – one electron is more tightly bound to the chloride than to the sodium.

Also, water is a polar liquid, that means, water molecules have a positive and a negative

side because the electrons charge is not distributed uniformly in the molecule.

Water molecules “stick” to each other because of their polarity.

When NaCl dissolves in water, water molecules

surround the sodium ion (Na+) neutralizing its charge with their negative

tails. The chloride ion (Cl-) is neutralized by water atoms surrounding it

with their positive sides oriented towards the chloride. NaCL is called an

electrolyte because it dissociates in ions in water. Figure 1 shows an NaCl ionic crystal dissolving into water. Water molecules

are negative on the oxygen side, positive to the side of the two hydrogen

atoms.

We are interested in electrolytes because

they can make water conductive and also because many kinds of batteries depend

on ionic reactions. The necessary ions are kept in water, wrapped in water

molecules and ready to be used for a certain chemical reactions.

3. Redox reactions

A battery is capable of delivering current,

i.e. a continuous electron flow, because the material used to build the negative

electrode releases electrons during a chemical reaction

whereas the material

in the positive electrode absorbs them. The negative electrode is called the

anode, the positive one is the cathode. This means that a chemical reaction

is releasing electrons at the anode and another chemical reaction is consuming

them at the cathode. Different types of batteries differ in the kind of reactions

in their interiors and industry is always looking for new technologies that

can deliver more stored energy for each gram of battery.

In a battery, the anode and cathode are

separated by the electrolyte, whose only mission is to transport ions from

one side to the other. The electrolyte can be purely liquid (as in car batteries)

or can be put inside a porous material which also acts as electrode separator.

The material in the negative electrode has to lose electrons - this is called

oxidation. The material in the positive electrode has to absorb electrons

- this is called reduction. For a battery we need two chemical reactions,

an oxidation and reduction pair, also called a redox reaction pair. The specific

example of NiCd batteries can make this clear.

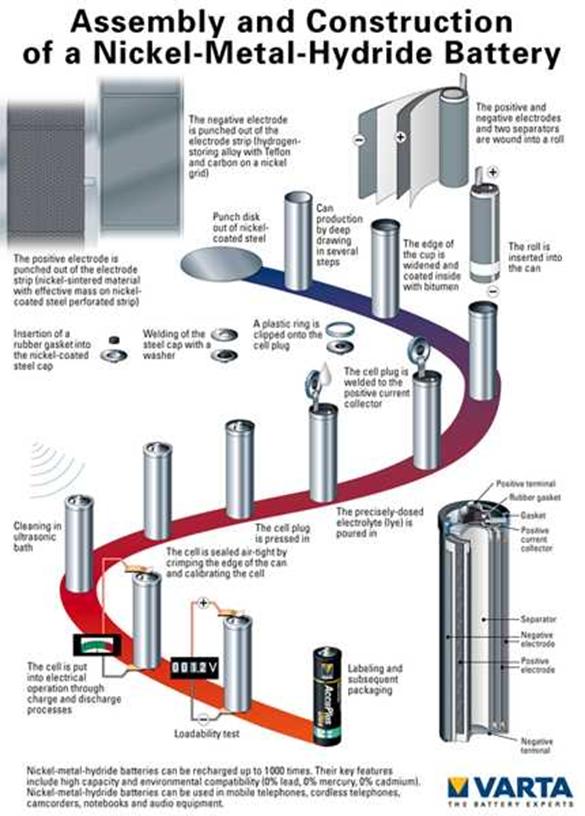

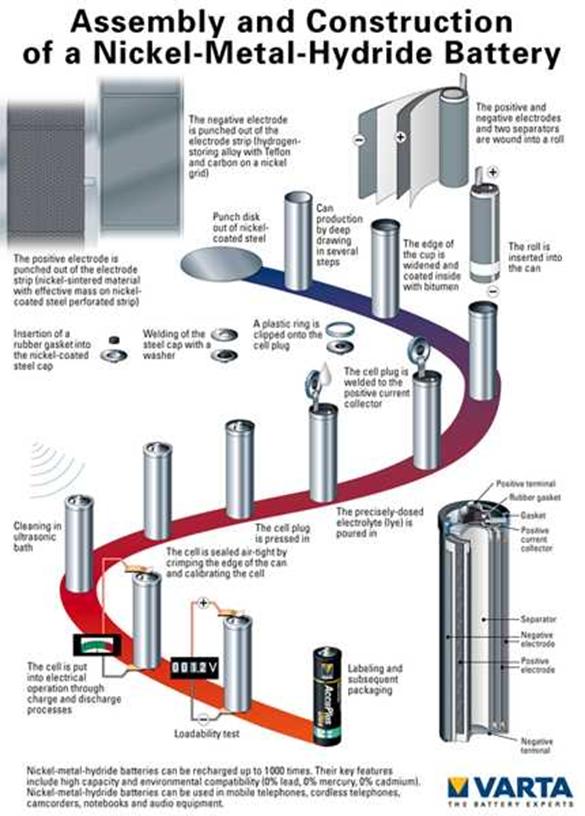

The diagram shows a picture of a cylindrical

NiCd battery. The negative and positive electrode are

sheets of material set apart by a separator soaked with electrolyte. The three

sheets are rolled as a cylinder, one of them is connected

to the positive, one to the negative collector. There is safety valve to eliminate

excess pressure from the chemical reactions.

In a charged NiCd battery, the cathode contains

nickel oxyhydroxide (NiOOH) and the anode contains cadmium. The electrolyte

consists of KOH, that is liquid potassium hydroxide.

Cadmium atoms at the anode dissolve spontaneously in the electrolyte and transform

in positive ions, releasing two electrons at the same time. This chemical

reaction is expressed as:

Cd

-> Cd+2 + 2e-

The cadmium ions combine immediately with

the OH- ions present in the electrolyte to form Cd(OH)2.:

Cd+2

+ OH- + OH- ->

Cd(OH)2

The chemical reaction at the anode can continue

because the electrons move out of the anode the moment an electric device

is connected to the negative and to the positive electrode. A current is established

and electrons flow towards the cathode.

At the cathode there is another spontaneous

reaction during battery discharge. Two electrons combine with nickel oxyhydroxide

and water to form nickel hydroxide:

NiOOH + NiOOH

+ 2e + H2O + H2O -> Ni(OH)2 + Ni(OH)2

+ OH- + OH-

The two reactions can be better visualized with the

following picture:

The curved line shows the reaction taking

place in the anode. There is a flow of two electrons from the anode to the

cathode.

During recharge of the battery the direction

of the arrow is inverted: the reactions are reversible and the original structure

of the electrodes is restored. The battery charger forces a current in the

inverse direction as during discharge and reverses the chemical reactions.

Of course this can be done only a fexied number of times, before the battery has deteriorated so badly that it

becomes unusable.

The main alternative to

NiCd batteries for small mobile robots are NiMH batteries. The positive

electrode contains nickel again, while the negative electrode contains some

kind of metallic alloy that can absorb hydrogen. Some alloys are very good

at that, absorbing many hydrogen atoms in its structure.

In NiMH batteries the reaction at the positive

electrode is exactly the same as in the case of NiCd batteries, as shown in

the figure. A water molecule is ionized, a proton and the electron attach

to NiOOH to form Ni(OH)2.

The reaction in the negative electrode takes

place when the metal releases the stored hydrogen and combines it with an

OH- ion to form water, setting free an electron:

MH

+ OH- -> M +

H2O + e-

The complete redox pair is similar to NiCd

batteries:

The formula of the redox pair obscures the

fact that electron transport takes place between the anode and cathode and

that the ion OH- is being also produced and absorbed at the electrodes. Since the transport

of electrons is very fast and since the transport of ions very slow, a reserve

of OH- ions is needed in the electrolyte. This is provided by the dissolved

potassium hydroxide, KOH.

4. Issues of battery

selection

The batteries used for mobile robots must

have a set of desired characteristics that limit the choices available. The

main issues are:

-

Geometry of the batteries. The shape of the batteries can be an important characteristic

according to the form of the robots.

-

Durability. We would

like to be able to recharge the batteries many times in order save costs.

-

Capacity. The capacity

of the battery pack in milliamperes-hour is important. It determines how long

the robot will run until a new charge is needed.

-

Initial cost. This is an

important parameter, but a higher initial cost can be offset by a longer expected

life.

-

Environmental factors. Used batteries

have to be disposed of and some of them contain toxic materials.

As an example: the batteries used in the

FU-Fighters 2002 robotic soccer team were packs of 8 NiMH units with a nominal

capacity of 2000 mAh. With this batteries the robots

could be used for several hours. The

size of the batteries allows them to be placed at the bootom of the robot.

5. Comparison of battery

types

Rechargeable batteries differ in several

important respects according to the technology used. In robotics, we are interested

in a batteries with high energy density, that is,

they should provide much power and be of low weight. NiCD and NiMH are the

most popular rechargeable batteries for robots, while Li-ion batteries are

used in laptops. The new Li-ion polymer and reusable alkaline batteries have

characteristics that could make them interesting in the future.

Charge

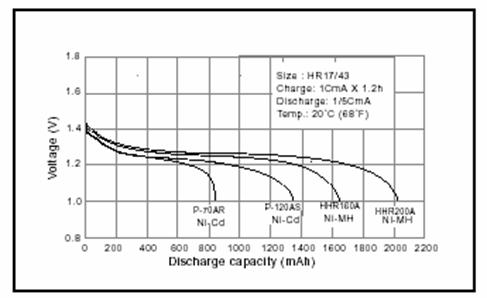

We will compare in what follows the NiCd

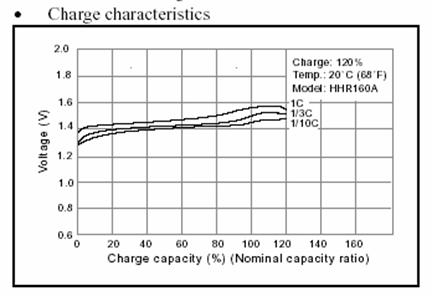

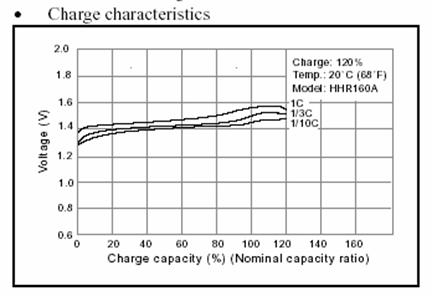

against the NiMH batteries. The first important parameter is how do both batteries charge. Figure x and y

show the charging curves for NiMH and NiCd batteries, respectively.

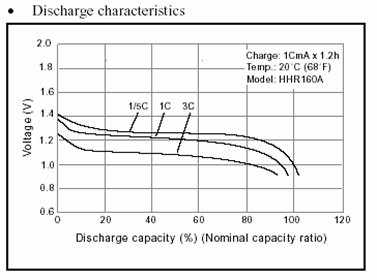

There are three curves in figure x. If the

nominal capacity of a battery is 160 mAh, for example, then 160 mA is called

a “C”. A C is the current that can be delivered by this specific battery during

an hour. Batteries can be charged by circulating through the battery a current

of one C, more than one C or a fraction of a C. Usually a fraction of a C

is used and this means that several hours are needed until the battery is

fully charged. The curve for NiMH batteries (Panasonic HHR 160A) shows that

the voltage increases slightly when the cell is gradually charged. These batteries

can be overcharged with 20% more energy than its nominal capacity. A charge

with one C leads to a slightly higher voltage in the cell as a charge with

1/3 C.

NiMH charging curve with three

different currents

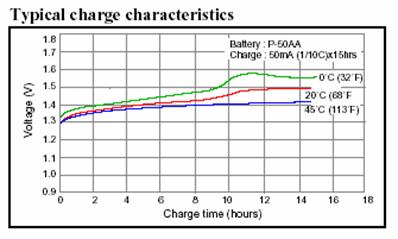

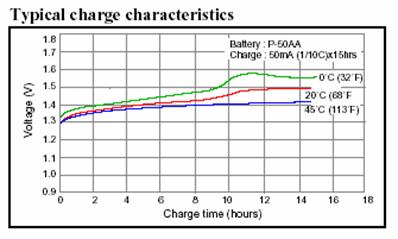

The next curve, for NiCd batteries, shows

that the voltage reached by the batteries is also affected by the temperature.

At 45 degrees Celsius the final voltage is 1.4 volts for each cell, at 0 degrees

it is more than 1.5 V.

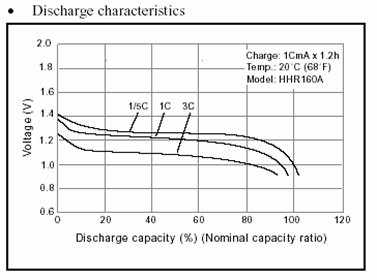

Discharge

Both NiCd and NiMH batteries have a flat

discharge curve. That means that the energy is extracted from the batteries

and the voltage only drops significantly when the capacity limit has been

reached. This is important for applications, since we would not like voltage

to degrade continuously as the battery’s energy is consumed. The curve shows

that if energy is extracted at a rate of 3C, then the voltage drops slightly

compared to the voltage obtained when the battery is delivering one C. The

curve shows that there is no precise way of determining from voltage alone

the state of the battery. The battery could be 20% discharged or 80% discharged

and it would still deliver almost the same voltage and the same current.

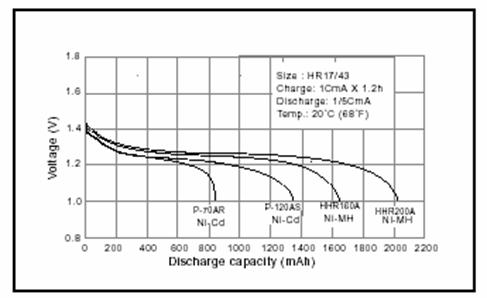

The next figure compares NiCd with NiMH

batteries. The NiCd batteries are rated at 700 and 1200 mAh. The

NiMH batteries at 1600 and 2000 mAh. NiMH can store more energy per

gram than NiCd batteries. Since Cd is toxic, this higher energy density and

greater conceniency has lead to a gradual substitution of NiCd by NiMH batteries.

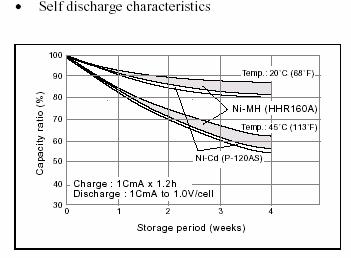

Retention

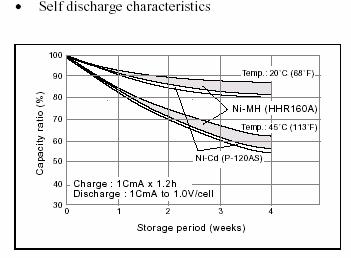

Charge retention is another important characteristic.

Depending on the battery manufacturer, this parameter can vary greatly. The

curve shows that NiC and NiMH batteries have similar retention ratios, which

vary according to temperature, but are nevertheless similar. At 20 degrees

Celsius the stored charge drops by less than 20% during a month. For other

manufacturers, the retention of NiMH batteries is usually worse than for NiCd

batteries.

Final comparison

The table below compares several different

types of batteries. Gravimetric density shows how many watts hour per Kilogram

can be extracted from a typical battery for each technology. A 100 Watt light

bulb consumes 100 Wh during an hour. While Li-ion

has a better energy density, they are difficult to recharge. NiMH has a better

energy density than NiCd. However, the internal resistance of NiMH batteries

is about 50% higher than for similar NiCd batteries. This means, that when

a current flows the heat dissipated in the battery is higher for NiMH than

for NiCd batteries. The peak load current for NiCd batteries is 20C. For example,

a 600 mAh battery can provide a peak current of 12 Amperes (20 times 0,6 A). The best result is obtained when one C, i.e. 600 mA,

is drained from this battery during continuous use. NiMH batteries can provide

a peak current of 5C. This can be an important parameter in the case of autonomous

robots, if the motors need to drain several amperes when they start accelerating.

If more current is drained, because the robot is stuck and the motors request

more and more energy, for example, the batteries get very warm and can be

damaged.

The table shows also that NiMH batteries

can be recharged, in general, fewer cycles than NiCd batteries.

|

|

NiCd

|

NiMH

|

Lead Acid

|

Li-ion

|

Li-ion polymer

|

Reusable

Alkaline

|

|

Gravimetric Energy Density (Wh/kg)

|

45-80

|

60-120

|

30-50

|

110-160

|

100-130

|

80

(initial)

|

|

Internal Resistance

(includes peripheral circuits) in mW

|

100

to 2001

6V pack

|

200

to 3001

6V pack

|

<1001

12V pack

|

150

to 2501

7.2V pack

|

200

to 3001

7.2V pack

|

200

to 20001

6V pack

|

|

Cycle Life (to 80% of initial capacity)

|

15002

|

300

to 5002,3

|

200

to

3002

|

500

to 10003

|

300

to

500

|

503

(to 50%)

|

|

Fast Charge Time

|

1h

typical

|

2-4h

|

8-16h

|

2-4h

|

2-4h

|

2-3h

|

|

Overcharge Tolerance

|

moderate

|

low

|

high

|

very

low

|

low

|

moderate

|

|

Cell Voltage (nominal)

|

1.25V6

|

1.25V6

|

2V

|

3.6V

|

3.6V

|

1.5V

|

|

Load Current

-

peak

- best result

|

20C

1C

|

5C

0.5C or lower

|

5C7

0.2C

|

>2C

1C or lower

|

>2C

1C or lower

|

0.5C

0.2C or lower

|

|

Operating Temperature (discharge only)

|

-40

to

60°C

|

-20

to

60°C

|

-20

to

60°C

|

-20

to

60°C

|

0

to

60°C

|

0

to

65°C

|

|

Commercial use since

|

1950

|

1990

|

1970

|

1991

|

1999

|

1992

|

Figure 1: Characteristics of commonly used

rechargeable batteries

6. The Memory Effect

Some kind of rechargeable batteries exhibit

the so-called memory effect: i.e. if they are not fully discharged during

several cycles, then the amount of power they can deliver diminishes with

time. It is as if the battery would “remember” that, for example, only 50%

of its capacity has been used many consecutive times and then, when more power

is required, it would not deliver more than 50% of the maximum capacity. NiCd

batteries can exhibit this effect, NiMH batteries also, but to a much smaller

degree.

The memory effect is a chemical transformation

of the electrodes. If a battery is not fully discharged several times, then

large crystals tend to build up at the electrodes. Large crystals diminish

the effectiveness of the chemical reactions in the battery cells. The picture

shows an electron photograph of the changes in the electrodes. To the left

we can see the corny structure of the electrode in its original state. The

porous structure maximizes the surface of the electrode and its contact with

the electrolyte. The chemical reactions take place at the normal rate. In

the middle we see an electrode in which a large crystal has built up. The

effective surface of the electrode has diminished by a large factor and the

chemical reactions are impaired. To the right we can see the same electrodes

after recovery, which is usually done by subjecting the battery to several

cycles of full charge and discharge.

Electron photograph of a NiCd electrode. To the left, original state of the electrode with

many cadmium hydroxide crystals. In the center a large crystal has

developed and the capacity of the battery has fallen by around 20%. To the right, the state of the reconditioned battery.

Electron photograph of a NiCd electrode. To the left, original state of the electrode with

many cadmium hydroxide crystals. In the center a large crystal has

developed and the capacity of the battery has fallen by around 20%. To the right, the state of the reconditioned battery.

The memory effect arises therefore, when

not all the active material in the battery is recycled by going through a

full charge-discharge cycle regularly. Battery analyzers can help in discharging and charging batteries during several

cycles at low currents. The battery need to be fully discharged several times

automatically. To avoid the memory effect, it is recommended to fully discharge

NiCd batteries at least once a month, and NiMH batteries

at least once every three months.

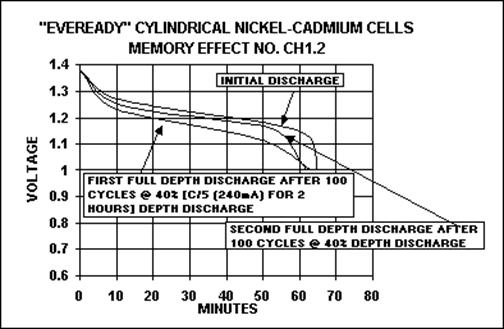

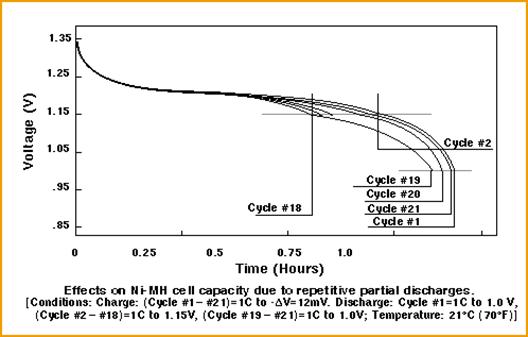

The picture below shows the development

of the memory effect for a NiCd battery. The first discharge takes around

an hour at the full battery rate (C) before voltage drops below 1.1 V. After

100 cycles of partial discharge, a full discharge leads to a noticeable voltage

drop after only 50 minutes. The battery yields now less power as originally.

The next full discharge shows that the battery has recovered a little, although

it is still not as good as originally.

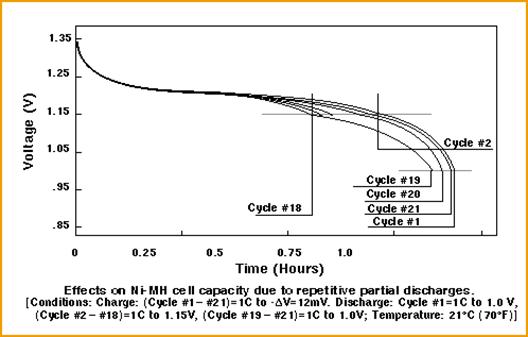

The next picture shows a small memory effect

for NiMH batteries. After 18 cycles of partial discharge (0.75 hours at 1C),

the discharge curve has moved down slightly. Several full discharge cycles

*19 to 21) bring the curve back near to the original discharge curve (cycle

1).

7. Conclusions

A battery is just a device which transforms

chemical energy in an electric current. There are several ways to do this,

according to the type of materials used. In general, a redox (reducing-oxidizing)

pair of reactions is needed. The negative electrode, the anode, oxidizes and

sets electrons free, whereas the cathode reduces and absorbs electrons. The

electrons travel from one electrode to another through a motor or a chip or

whatever device is connected to the power source.

NiCd batteries have been traditionally used

for small robots, since they have been in commercial use since the 1950s.

Their advantages are:

-

fast and simple to recharge

-

can service high peak loads

-

survive many recharge cycles

-

economical, rugged and with long shelf-life

Their disadvantages are their lower energy

density compared to NiM batteries and their toxicity

for the environment.

NiMH batteries are replacing NiCd batteries

due to their higher energy density, but have a shorter life (in terms of charge-discharge

cycles). They cannot deliver as much energy as NiCd for peak loads, and this

can be a disadvantage if a robot occasionally drains much concentrated energy.

They are less prone to suffer the memory-effect than NiCd batteries.